References

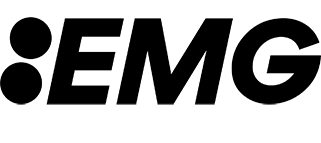

Pile Cage Machine in the United States

Last week the first updated SLP Pile cage machine was installed in the United States

Suitable for cages up to a diameter of 1500 mm and a length of 20 meters. This machine is equipped with many new features, such as setting aid, automatic clamping, automatic welding system and adjustable welding time. In addition, it is very robust. Huge time savings are achieved with these features. Both our customer and we are very satisfied with the cooperation! Let many follow!

Piling

Piles are columnar elements in a foundation that can transfer load from the superstructure through weakly compressible strata or water onto stiffer or more compact and less compressible soils or rock. They may be required to carry uplift loads to support tall structures subjected to overturning forces from winds or waves.

The importance of the reinforcing ring

The internal reinforcing ring may be used where it is necessary to develop the complete external skin frictional resistance of the pile cage.

Hard driving through strongly resistant layers or sitting a pile onto a rock may split or tear the ring shoe.

In the case of hard-driving, it is preferable to adopt a welded-on thick plate shoe designed so that the driving stresses are transferred to the parent pile over its whole cross-sectional area.

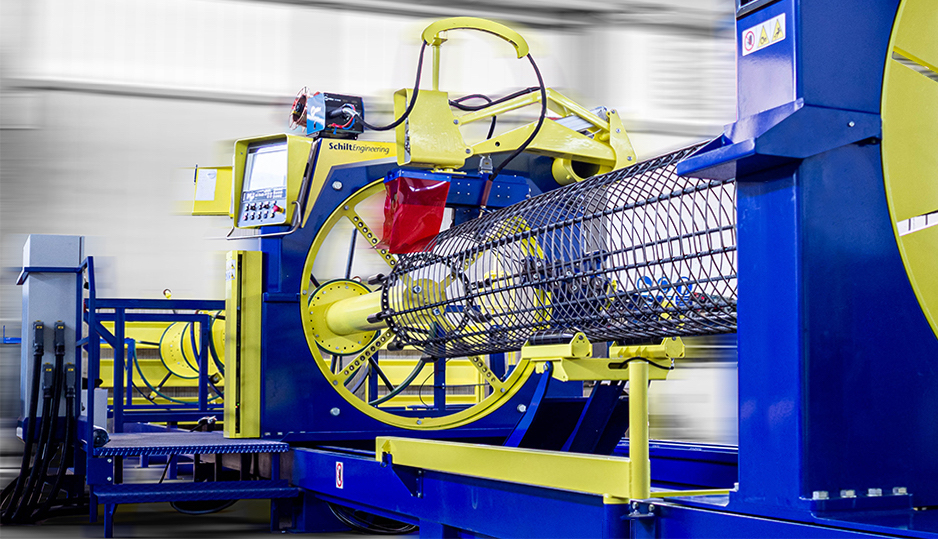

Robotic assembly of rebar cages

Robust welding robot with exchangeable welding units for producing round or polygonal cages. Two welding machines for welding spiral on both sides of longitudinal bars are an option. Exact guiding and flexible guide rollers guarantee a precise welding point—computer-controlled welding speed which automatically determines the maximum speed possible.

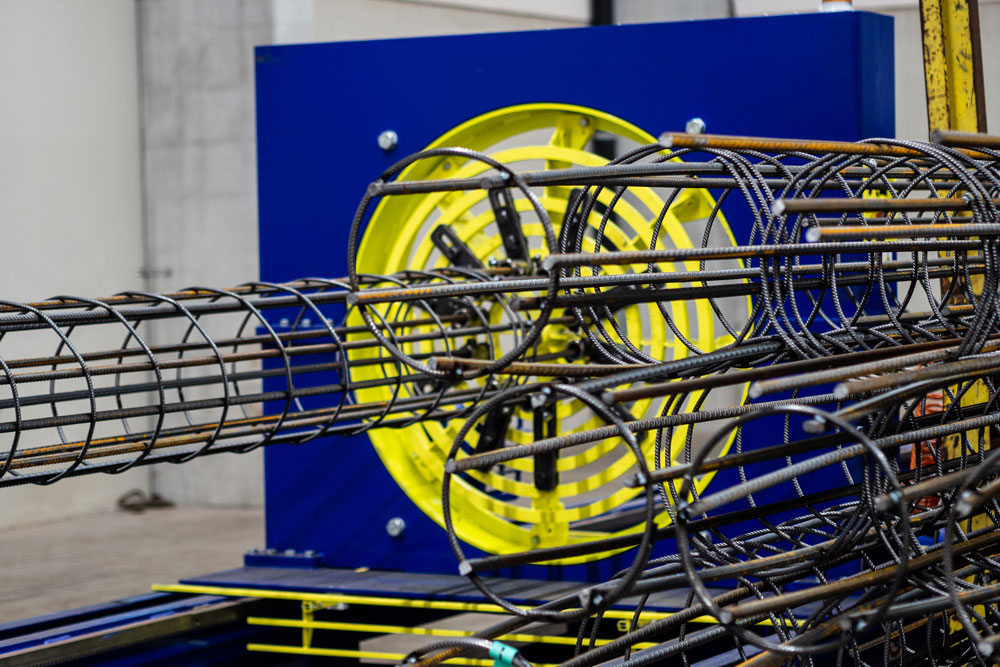

The reinforcement cage processing

Reinforcement cage in accordance with the design drawings over like making. Installation of flange reinforced by localization, localization of the flange has the advantages of convenient operation, accurate positioning, high efficiency.

Region: Germany, year 2018

Schilt Engineering: Planning and delivery of an automatic rebar shearline with double benders, as well as a logistics system for straightening machine from coil.

Region: United Kingdom, year 2018

Schilt Engineering: Design and delivery of highly automated rebar shearline MULTIBAR500 with connected rebar double benders and logistics.

Region: Hong Kong, year 2017

Schilt Engineering: Planning and delivery of 2 highly automated rebar shearlines with combined internal warehousing and multiple double bender.